We're sometimes asked "why should I buy an aluminium PolaStorm propeller, and not someone else's?". Well, there are a number of reasons, but probably the one that grabs people's attention the most is when we share that PolaStorm use Titanium and Strontium, along with Aluminium in the alloy....

Why?

Titanium and strontium are two elements that can be added to aluminum alloys to improve their properties. Here are some benefits of adding titanium and strontium to aluminum alloy:

-

Improved strength: Titanium and strontium can increase the strength of aluminum alloys. This can lead to better performance and longer lifespan of the alloy in applications where high strength is required.

-

Enhanced corrosion resistance: Both titanium and strontium can improve the corrosion resistance of aluminum alloys. This can be particularly important in marine or aerospace applications where the alloy is exposed to harsh environments.

-

Reduced grain size: The addition of titanium and strontium can help to refine the grain size of aluminum alloys, leading to better mechanical properties such as increased ductility, toughness, and fatigue resistance.

-

Improved casting properties: Titanium and strontium can improve the casting properties of aluminum alloys, making them easier to cast and resulting in less porosity and defects in the final product.

-

Cost-effective: The addition of titanium and strontium to aluminum alloys is a cost-effective way to improve the properties of the alloy, as it does not significantly increase the cost of the material.

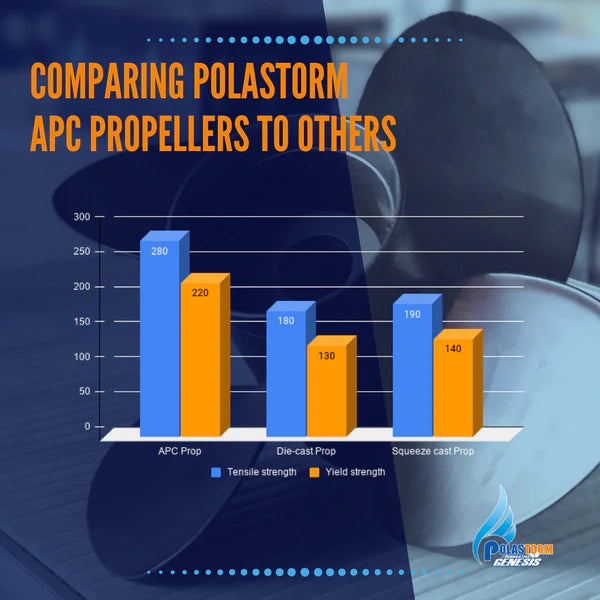

Overall, adding titanium and strontium to aluminum alloys can significantly improve their properties and make them suitable for a wider range of applications, particularly in industries such as aerospace, automotive, and marine engineering. Polastorm call this APC: Aerospace Precision Casting technology.